Engine Monitoring System

Serves as:

- A sophisticated system that provides thorough performance information for all types of Diesel Engines

- A Predictive Maintenance tool can save your company thousands of US$$$$$$$.

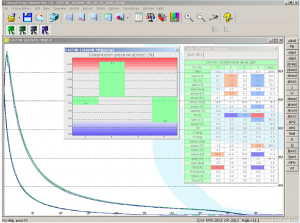

EMS is an advanced cylinder pressure and acoustic emissions based monitoring sys-tem. The system incorporates sensors and flywheel pickups of ultimate quality and ac-curacy. It is designed for use on all types of two or four stroke slow, medium or high speed engines (even V-type engines).

EMS turns any PC into a Diesel Engine Combustion Analyzer allowing real time en-gine measurement and tuning. Our Monitor-ing systems can be used to monitor as many diesel engines that may exist onboard a ves-sel. It runs under any Windows including 2000, XP & Newer.

Benefits

- Accuracy

- Environmental Operation of your Engines by Optimizing Combustion

- Real Time Engine Tuning

- User Friendliness

- Best Value for Money that the Marine Market can currently offer

- Protects from Costly Downtime

- A Single Operator can run the Entire System

- Real Time Engine Tuning

- Cost Savings on Parts and Labor. Replacement of parts is based on need and not on time intervals

- Engine Efficiency is increased by the use of thorough Information and Evaluation of your Engine’s Timing incorporating the Performance of you Fuel Pumps and Injectors

- Balances Output, Extends Engine Life and Increases performance

- Assists in reducing Emissions to be Environmentally Compliant

- Small Measurement Files for quick transfer to home office via e-mail

- Comprehensive Technical Support

Performance Data

- P – A, P – V, Light – Spring Diagrams

- P(i), p(ind), p(ign), p(comp), p(max), p(exp)

- RPM, A(ign), A(max),

- Lambda, W, ℓ, VIT, a(pmp), a(opn), a(inj), l(ing)

Available Configurations

- Multisensor 24h monitoring

- One sensor hardwired system

- Laptop version

- Portable handheld version

Scope of Supply

A) EMS System Complete suitable to monitor the performance of: One (1) Main Engine (2 or 4 stroke)

B) EMS System Complete suitable to monitor the performance of: One (1) Main Engine (2 stroke) and three (3) Auxiliary Engines (4 stroke)

Optionally we can offer the following:

- Fuel Acoustics Emission Sensors (Exclusive only for AMS’s systems)

-

- Thus sensor allows you to prolong the life of your injectors and fuel pumps while keeping the downtime and costs of replacement spare parts to the minimum.

- Controlling fuel afterburning has never been easier.

- With the above sensor you have the prospect for a full investment return of its cost and of the systems as well

- No penetration into the fuel system eliminates possible fuel leakage.

- Latest Technology in Acoustic Emissions

- Unique to the Market

- Applicable to both 2-stroke and 4-stroke Engines

- Extended Life Cycle as compared to pressure sensors

- Scavenge Air Pressure Sensors

The detailed brochure

Contact Advanced Marine Solutions Hellas today to learn more and speak with our experienced staff about all your company’s needs

- A reference list of satisfied customers

Recent Comments