AMS Torque Meter System (TMS)

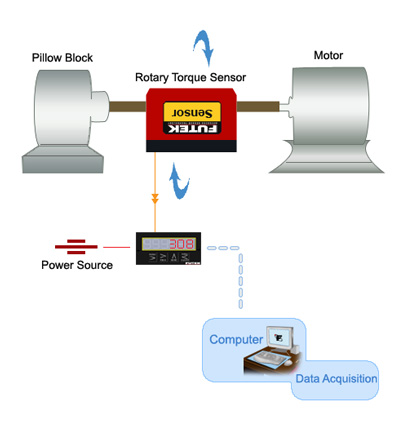

This is a permanent monitoring system which measures the actual (effective) power output of any diesel engine at all times. The torque meter consists of 2 metal tapes with magnetic pattern, two sensors and a transmitter. The tape provides 150~600 pulses per revolution. The sequential magnetic north and south poles of the tape are detected by the sensors. Then the microprocessor based transmitter detects the shift of pulses of the second tape (the twist of the shaft) and calculates the torque. The measurements can be then transferred to a P/C for further evaluation of the results.

With TMS you can measure :

- Shaft Power

- Shaft torque

- RPM

- Average Torque, Power and RPM, set from 2 to 250 revolutions.

Features:

- High precision, Resolution 100 Nanoseconds or 2 x 10-5 degrees at 120 RPM

- User friendliness

- Fully automated zero calibration procedure

- Last 48 hours records of measured Power

- Average Power for selected periods of time (up to 48 hours)

- Contact Free Digital Sensors (No strain gauges)

- Simple & Easy to Install

- Maintenance Free System

- 24 V.D.C power

- 2×4-20 mA output signal

- 1x digital RPM output

Optional Features

- Fuel Flow

- Fuel temperature

- Vessel’s speed

Three (3) measurement display options:

- Through a PC in the ECR

- Through a 2 x 16 character display located near the shaft.

- Through the control system of the vessel.

PC Software Capabilities:

- Specific Fuel Oil Consumption, SFOC (external flow meter required)

- Total Fuel By Mass/Volume

- Fuel Consumption per Nautical Mile

- Comparison with Reference Propeller Curve

- Comparisons of Actual versus Reference data

- Data Log File

- Trends and Graphs

- Various Report Functions

- TMS can, optionally, be interfaced with EMS

-

Contact Advanced Marine Solutions Hellas today to learn more and speak with our experienced staff about all your company’s needs.